Hart to Modbus converter is designed to process two completely different hardware port and data communication standard. By processed by MCU within Hart and Modbus, the most used parts of two protocols are converted for on-site monitoring and communication.

Modbus have been very popular in industry communication, maybe it is not the best protocol, but it is a good and easy protocol to use. Hart protocol is not suitable for large quantity network.

The Hart to Modbus converter is developed and tested on basis of pressure transmitter of Honeywell and IFC300 flow meter from Kronhe.The hart converter can monitor HART protocol instruments and have been compatible with instruments from E+H,Rosemount,Honeywell,FUJI,SIMENS,Yokogawa and Krohne,and can read their current pressure,flow rate,flow totalizer,etc.

Technical Features:

1).A RS232C port (9 holes)

2).A RS485 port

3).Serial port parameters: 9600-None-8-1

4). Manual or automatic data reading way available

5).The quickest response time for manual data reading: 1.1s

6).The quickest response time for automatic data reading: 0.3s

7).Support MODBUS,ASCII and Hart way

8).Converter has own address and the default is 10H. Instrument address has no sense for application.

9).Hart instruments can Max 16 nos of parameters and parameters type can be user-defined.

10).The unit of HART instrument’s parameters can be set by MODBUS protocol.

11). Type of Hart instrument is optional, or also user-defined. The default is IFC300 flow meter.

Technical specification:

1. Power supply: DC8-36V,current <20mA

2.Power consumption: less then 0.2W

3.Temperature: -25~+70 Degree C.

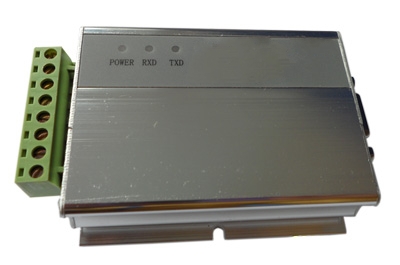

4.Enclosure meterial: aluminium

5.Dimensions: 81×66×26mm

Special notice: the Hart to Modbus converter is developed on the basis of Modbus protocol and used to communicate with HART instruments by protocol converting. The Hart Modbus converter can mainly convert the most used parts of protocols, so it may not work well for all of HART instruments with default software configuration. Thus, if have different requests, please feel free to contact and tell us detailed information of your application and our engineers can make special configuration as requirement.